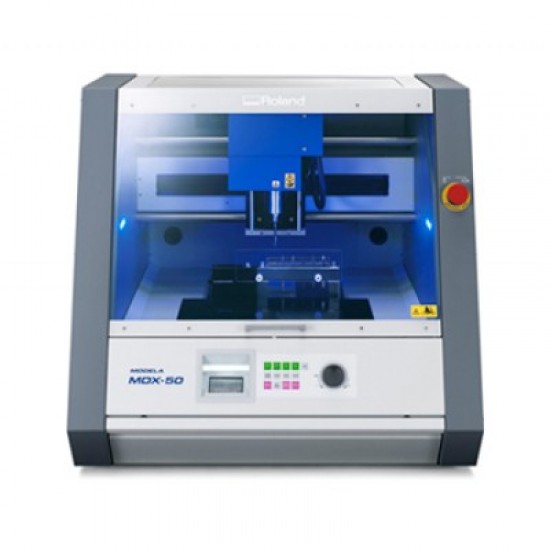

Roland MDX-50 Benchtop CNC Mill

- AGFA

- Anapurna

- ARIZONA

- BCN3D

- BEST SELLER

- CANON

- DAIGE

- Dental Milling Machines

- EPSON

- FORMLABS

- GBC

- GRAPHTEC

- HASSELBLAD

- Heat Press Machine

- HP

- KONICA

- LEDCO

- LulzBot

- MakerGear

- MIMAKI

- MUTOH

- PRINTER MACHINE

- PRINTERS PARTS

- PRO-LAM

- PRUSA

- Renfert

- RICOH

- Roland Dental Milling Machines

- roland printer

- ROYAL SOVEREIGN

- SCITEX

- SEIKO

- SIGNATURE

- SISMA

- SPECTRA

- SUMMA

- Surgical Loupe

- TAMERICA

- Top Rated

- TOSHIBA

- Type A Machines

- U-MARQ

- Ultimaker 3D Printer

- VALUELAM

- XAAR

- XYRON

- ZORTRAX

- Desktops

- Laptops & Notebooks

- Components

- Tablets

- Software

- Phones & PDAs

- Cameras

- MP3 Players

Your shopping cart is empty!

Product Description

MODELA MDX-50 Benchtop Milling Machine

- Benchtop CNC machine for rapid prototyping

- 5-station Automatic Tool Changer - continuous operation without stopping to change tools

- Expanded machining area 15.7” (X) x 12” (Y) x 5.3” (Z)

- Improved drive system supports dimensional stability – smooth prototyping with millimeter accuracy

- Bundled with user-friendly CAM software

- Optional Rotary Axis with self-centering headstock and tailstock workpiece clamps

Other Distinguishing Features

- Advanced drive system supports dimensional stability – create prototypes with millimeter accuracy

- Large machining area plus enhanced machine rigidity and drive mechanics

- Optional Rotary Axis with self-centering headstock and tailstock workpiece clamps

- Simple-to-load tools and automatic machine calibration

- Requires no special electrical set-up and needs no additional air compressor

- Multi color-coded LED status light notifications and email notifications inform users of machine status

- Built-in debris collection drawer with rail guided safety door for safe and clean production

- Ideal for use in studio and educational environments

- Advanced drive system supports dimensional stability – create prototypes with millimeter accuracy

- Large machining area plus enhanced machine rigidity and drive mechanics

- Optional Rotary Axis with self-centering headstock and tailstock workpiece clamps

- Simple-to-load tools and automatic machine calibration

- Requires no special electrical set-up and needs no additional air compressor

- Multi color-coded LED status light notifications and email notifications inform users of machine status

- Built-in debris collection drawer with rail guided safety door for safe and clean production

- Ideal for use in studio and educational environments

Mill Fine Details and Smooth Finishes

With an improved drive system, machine rigidity and enhanced drive mechanics, the MDX-50 mills incredibly smooth and accurate prototypes for testing structure, function, and assembly with other parts. A machining area of 15.7”(400mm) (X) x 12”(305mm) (Y) x 5.3”(135mm) (Z) supports production of large single objects or batch production of smaller multiple parts.

Free Your Time

The automated features of the MDX-50 enables users to mill with speed and confidence. Combine the 5-station ATC and optional rotary axis unit for the most automated and precise operation:

- Auto-sensing function corrects the tool length to ensure milling accuracy for every job

- Optional rotary axis for effortless production of complex surfaces:

- Includes a wide, self-centering headstock and tailstock workpiece clamps

- Auto-rotates materials from 0-to-360 degrees

- Indexes for 2-sided, 4-sided and custom angles

The automated features of the MDX-50 enables users to mill with speed and confidence. Combine the 5-station ATC and optional rotary axis unit for the most automated and precise operation:

- Auto-sensing function corrects the tool length to ensure milling accuracy for every job

- Optional rotary axis for effortless production of complex surfaces:

- Includes a wide, self-centering headstock and tailstock workpiece clamps

- Auto-rotates materials from 0-to-360 degrees

- Indexes for 2-sided, 4-sided and custom angles

Superior Reliability and Support

The MDX-50 represents the most reliable technology backed by unmatched customer service and technical support, and comes with a comprehensive one-year manufacturer’s warranty.

Roland DG's international ISO certifications are your assurance of our commitment to quality products and service.

Roland DG's international ISO certifications are your assurance of our commitment to quality products and service.

| MODEL | MDX-50 | |

|---|---|---|

| Acceptable materials* | Resins such as chemical wood and modeling wax (metal not supported) | |

| Operating range | X: 15.75in (400mm) Y: 12.00in (305mm) Z: 5.315in (135mm) | |

| Table size | W: 15.75in (400mm) D: 12.00in (305mm) | |

| Loadable workpiece size | X: 15.75in (400mm) | |

| Axis drive | Stepper Motor | |

| Feed rate | XY: 0.3in to 141.7 in/min (7 to 3600mm/min) Z: 0.3 to 118.1 in/min (7 to 3000 mm/min) | |

| Software resolution | RML-1: 0.001 mm/step NC code: 0.001 mm/step | |

| Mechanical resolution | 0.01 mm/step (0.39 mil/step; half step) | |

| Spindle motor | Brushless DC motor | |

| Spindle rotation speed | 4500 ~ 15000 rpm | |

| Tool chuck | Collet | |

| Tool Change Method | AutomaticTool Changer (ATC) | |

| ATC Magazine Capacity | ||

| 5 Tools + 1 Detection pin (6 Position Capacity) | ||

| Tool Shank Diameter | 0.250in, 0.125in (6.35, 3.175mm) | |

| Operating noise | During operation | |

| Dust box dimmensions | 23.62 x 27.65 x 3.74in (600 x 700 x 95mm) | |

| Interface | USB | |

| Power requirements (VAC/A) | AC 100 to 240 V ±10%, 50/60 Hz, 1.2 A (Overvoltage Category: II, IEC 60664-1) | |

| Power consumption (W) | ≈ 95W | |

| Acoustic noise level (dB) | No-load operation: | 60 dB (A) or less |

| Standby: | 45 dB (A) or less | |

| External Dimensions | Width X Depth x Height: | 29.92 × 35.43 × 28.82 in (760 × 900 × 732 mm ) |

| Weight | 269lb (122kg) | |

| Installation environment | Indoor use at altitudes | Up to 6500ft (2000 m) |

| Temperature | 41 to 104°F (5 to 40°C) | |

| Humidity | 35 to 80%RH (no condensation) | |

| Ambient pollution degree | 2 (as specified by IEC 60664-1) | |

| Short-term temporary overvoltage | 1440 V | |

| Long-term temporary overvoltage | 490 V | |

| Included items | Power cord, USB cable, manual, Roland DG Software Package CD, detection

| |

| Optional ZCL-50A Rotary Axis Unit | ||

|---|---|---|

| Operating range | X: 14.29 in (363mm) - Machine Coordinates 1.46 to 15.75 in (37 to 400 mm) Y: 12.01 in (305 mm) Z: 4.92 in (125 mm) A: A: ±2146680° (approximately ±5963 rotations) | |

| Loadable workpiece size | 4.72 in (120mm) - 2.36 in (60mm) maximum radius from center of rotation | |

| Loadable workpiece length | 14.96 in (380mm) | |

| Workpiece clamp thickness | 0.39 to 2.56 in (10 to 65mm) or 0.79 to 2.68 in (20 to 68mm) Diameter | |

| A axis motor | Stepper Motor | |

| Mechanical Resolution | 0.0225°/step (half step) | |

| Dimensions | Width X Depth x Height: | 22.76 × 7.48 × 5.04 in (578 × 190 × 128 mm) |

| Weight | 15.43 lb (7kg) | |

| Included Items | Detection bar, cap screws, user's manual

| |

| System Requirements | |

|---|---|

| OS | Windows 10, 8.1, 7 (32- or 64-bit version)*1,*2,*3 |

| CPU | Minimum required CPU for the operating system |

| Memory | Minimum amount of required RAM for the operating system |

| Optical drive | CD-ROM drive |

| Video card and monitor | A display with at least 16-bit color and a resolution of 1024 × 768 or more is recommended. |

(*1) This software is a 32-bit application and therefore runs in WOW64 (Windows-On-Windows 64) when running on 64-bit versions of Windows operating systems.

(*2) Internet Explorer 8.0 or later is required.

(*3) Operations have not been verified in virtual Windows environments such as Hyper-V and Virtual PC.